Rotating Disk Sorptive Extraction

by Prof. Dr. Pablo Richter, Department

of Inorganic and Analytical Chemistry, Faculty of Chemical and Pharmaceutical

Sciences, University of Chile.

The modern trends in

analytical chemistry promote efficiency and green technology in sample

preparation. In this context, our research team developed a new technique in

2009 that is capable of extracting pollutants from liquid samples on a rotating

PTFE disk with one surface coated with an extraction phase [1]. The disk has

embedded a miniature magnetic rod, which allows rotation. We have termed this

procedure rotating-disk sorptive extraction (RDSE).

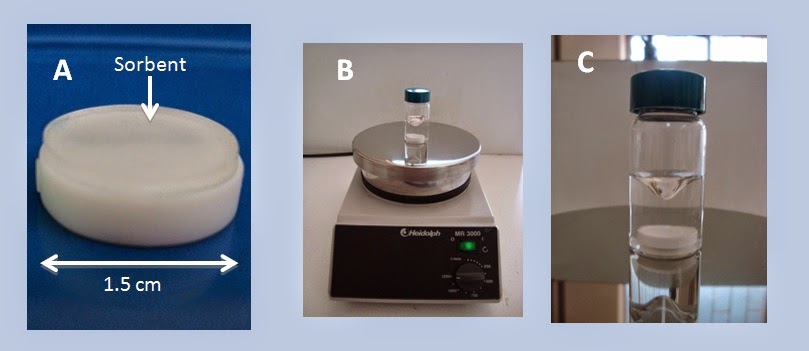

RDSE is currently

available in two configurations. In the classic version (Figure 1), the extraction

phase is a polymeric film adhered to one side of the PTFE disk (configuration

1). In this configuration, polydimethylsiloxane (PDMS), nylon and octadecyl

(C18) have been used as the sorptive material for the extraction of

low-polarity analytes (Log Kow between 3 and 7) [1-12]. However, for more polar

analytes, quantitative recoveries are not achievable with short extraction

times [2].

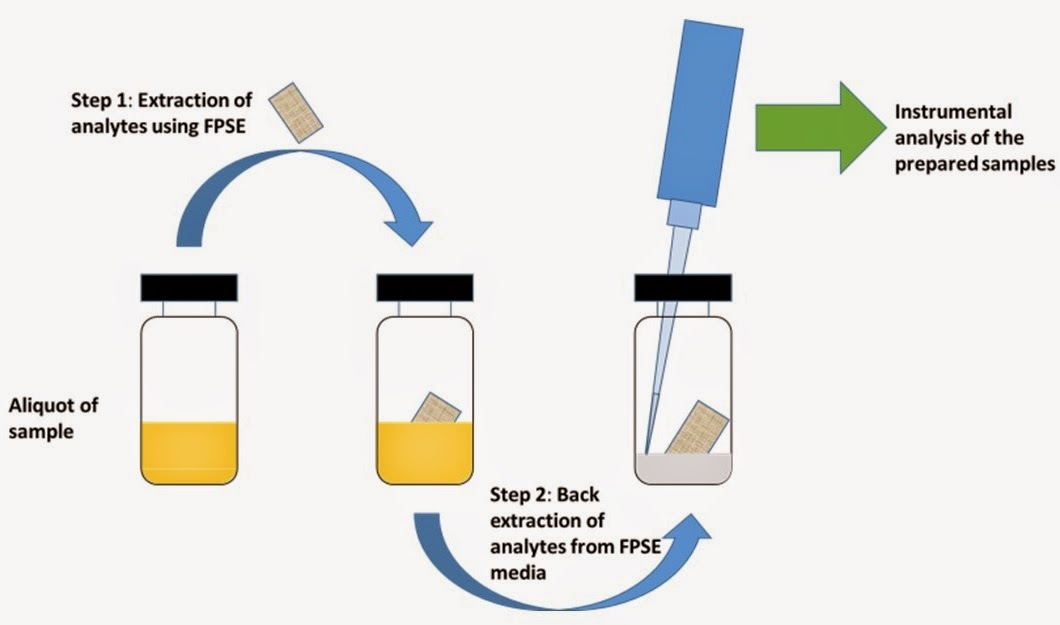

The second RDSE version

(configuration 2) [13,14] consists of a disk that contains a cavity that is

loaded with an extraction phase and is then covered with a glass-fiber filter

and sealed with a ring of Teflon (Figure 2). This configuration was

successfully employed for the extraction of florfenicol from porcine plasma [14]

and non steroidal anti-inflammatory drugs (NAIDs) in water using Oasis® HLB as

the sorptive material [13]. The use of the disk with cavity allows the

incorporation of commercial or synthesized SPE extraction phases and maximizes

the sorptive capacity by recirculating the sample through the phase using the

rotating disk technology. Molecularly imprinted polymers (commercial or

synthesized in the laboratory) can also be employed as an alternative to HLB,

thereby enabling improved selectivity, and extraction efficiency.

|

| Figure 2. Rotating disk with a cavity in which an extraction phase is loaded and is then covered with a glass-fiber filter and sealed with a ring of PTFE. |

From a theoretical

point of view, thermodynamic and kinetic parameters are critical factors in the

efficiency of a given microextraction technique. Both kinds of parameters must

be considered because the main objective of these techniques is to achieve efficient

analyte extraction in a reasonable time [15, 16]. Previous studies of the partitioning of

organic compounds between PDMS and water suggested that the overall mass

transfer of low-polarity organic compounds is not limited by internal diffusion

in the PDMS but rather by diffusion in the aqueous boundary layer [7, 17-19].

Thus, the rate-determining step in the equilibrium extraction time is the

diffusion of the analytes through the water boundary layer. Efficient stirring

of the sample contacting the sorptive phase is necessary to achieve the

partition equilibrium as rapidly as possible, because the thickness of the

boundary layer is reduced when the rotating velocity is increased [15,20]. Further,

initial extraction rate is roughly proportional to the surface area of the

extraction phase [15], consequently the equilibration time can be greatly

shortened when the extraction device provide a larger surface area/volume ratio.

The extraction device

used in RDSE exhibits an extraction phase with a high surface-area-to-volume

ratio and can be stirred at much higher velocities than the stir bar used in

SBSE without damaging the phase, because the extraction phase is only in

contact with the liquid sample. Thus, higher rotating velocities facilitate

analyte mass transfer to the sorptive surface [1,10-13].

These two

configurations of the extraction device provide to RDSE a highly versatility,

since any sorptive material used in both SPE and SBSE could be immobilized on

the rotating disk. In addition, RDSE provides some advantages over SPE,

especially by allowing the recirculation of the sample through the extraction

phase and, thus, maximizing its sorptive capacity (in SPE, the sorption occurs

while the sample passes unidirectionally through the solid support).

Furthermore, in RDSE, the interface is continuously renewed during the

extraction process, which minimizes the involved cleanup steps for complex

samples that are required with SPE.

Other important

characteristics of RDSE are related with the geometry of the extraction device,

which allows an easier automation of the extraction process [8], a direct

spectroscopic measurement in the extraction phase [4-6], and the feasibility of

the use in bioavailability studies [12].

Recently a novel

automatic sorptive microextraction approach combining sequential

injection-based programmable flow with rotating disk sorptive extraction (RDSE)

was proposed for the clean-up and concentration of low polarity organic species

in urine samples [8]. Compared to its batch counterpart [13], the main

advantage of the proposed dynamic method is its improved sample throughput with

sample preparation times decreasing from 90 min to merely 15 min when the

SI-RDSE is used.

Most of the

microextraction techniques have primarily been used with gas or liquid

chromatography. However in RDSE the analyte can also be directly evaluated

using solid phase spectroscopy in the solid phase because of its geometry. In

this context, RDSE methods have been described associated to spectrophotometry

[4-6] and to excitation-emission fluorescence spectroscopy [9].

Table 1 shows the

applications of RDSE by using both disk configurations. Complex samples such as

wastewater, plasma, urine can also be analyzed because large molecules such as

proteins and lipids cannot pass rapidly across the water boundary layer.

Table

1.

Applications of RDSE in different samples associated to various analytical

techniques.

Analyte

|

Disk configuration/

sorbent

|

Sample

|

Technique

|

Reference

|

Alkylphenols

|

1/PDMS

|

River water

|

GC-MS

|

1

|

Pesticides

|

1/PDMS

|

River water

|

GC-MS

|

2

|

PAHs

|

1/PDMS

|

Waters

|

GC-MS

|

3

|

Cristal violet

|

1/PDMS

|

Fish- farming

water

|

Spectrophotometry

|

4

|

Malachite green

|

1/PDMS

|

Fish- farming

water

|

Spectrophotometry

|

5

|

Copper

|

1/PDMS

|

Drinking water

|

Spectrophotometry

|

6

|

Hexachlorobenzene

|

1/C18

|

Waters

|

GC-ECD

|

7

|

Diclofenac and

ibuprofen

|

1/C18

|

urine

|

SI-HPLC-DAD

|

8

|

PAHs

|

1/Nylon

|

Waters

|

Fluorescence

|

9

|

Triclosan and

methyl-triclosan

|

1/PDMS

|

Wastewater

Soil leachates

|

GC-MS

|

10-12

|

NSAIDs

|

2/HLB

|

Wastewater

|

GC-MS

|

13

|

Florfenicol

|

2/HLB

|

Plasma

|

HPLC-DAD

|

14

|

Acknowledgements

Fondecyt, Chile

(Projects 1140716 and 1100085) is gratefully acknowledged for financial

support.

References

[1]

P. Richter, C. Choque,

A. Giordano, B. Sepúlveda, J. Chromatogr. A 1216 (2009) 8598–8602.

[2]

A. Giordano, P. Richter,

I. Ahumada, Talanta 85 (2011) 2425–2429.

[3]

Y. Corrotea, K. Sánchez,

M. A. Rubio, P. Richter, J. Chil. Chem. Soc., 49 (2014) 2477-2480.

[4]

V. Manzo, O. Navarro,

L. Honda, K. Sánchez, M. I. Toral, P. Richter, Talanta 106 (2013) 305–308.

[5]

P. Richter, A. Cañas,

C. Muñoz, C. Leiva, I. Ahumada, Anal. Chim. Acta, 695 (2011) 73–76.

[6]

C. Muñoz, M. I.

Toral, I. Ahumada, P. Richter, Anal. Sci., 30 (2014) 613-617.

[7]

A. Cañas, P. Richter,

Anal. Chim. Acta 743 (2012) 75– 79.

[8]

V. Manzo; M. Miró; P.

Richter, J. Chromatogr. A 1368 (2014) 64–69.

[9]

A. Cañas, P. Richter,

G. M. Escandar, Anal. Chim. Acta 852 (2014) 105–111

[10]

L. Jachero, B.

Sepúlveda, I. Ahumada, E. Fuentes, P. Richter. Anal. Bioanal. Chem. 405 (2013)

7711–7716.

[11]

L. Jachero, I. Ahumada,

P. Richter. Anal. Bioanal. Chem. 406 (2014) 2987–2992.

[12]

L. Jachero, I.

Ahumada, E. Fuentes, P. Richter. Chemosphere 119 (2015) 1062–1067.

[13]

V. Manzo; L. Honda, O. Navarro, L. Ascar, P.

Richter. Talanta 128 (2014) 486–492.

[14]

A. Cañas, S.

Valdebenito, P. Richter. Anal. Bioanal. Chem. 406 (2014) 2205–2210

[15]

Z. Qin, L. Bragg, G.

Ouyang, J. Pawliszyn, J. Chromatogr. A 1196-1197 (2008) 89-95.

[16]

R. Lucena, Anal. Bioanal. Chem. 403 (2012)

2213–2223.

[17]

T.P. Rusina, F. Smedes,

J. Klanova, K. Booij, I. Holoubek, Chemosphere 68 (2007) 1344-1351.

[18]

P. Mayer, U. Karlson,

P.S. Christensen, A.R. Johnsen, S. Trapp, Environ. Sci. Technol. 39 (2005)

6123-6129.

[19]

J.H. Kwon, T. Wuethrich,

P. Mayer, B.I. Escher, Anal. Chem. 29 (2007) 6816-6822.

[20]E. Baltussen, P. Sandra, F. David, C. Cramers, J. Microcol.

Sep. 11 (1999) 737-747.

About

the author

Comments

Post a Comment